The BERICAP Closure Solutions

We are an experienced, trusted solution provider developing innovative, high-quality closures for food, beverage, and industrial applications. We accompany you through every step of the closure selection and development process. Our leak-proof designs ensure secure transport and storage, protect against counterfeiting, and give customers a smooth, easy-to-use experience that strengthens your brand’s image.

Consumer Convenience

Maximizing Customer Satisfaction with Easy-to-Use Closures

The right closure can make a difference in customer satisfaction. At BERICAP, we are a trusted solution provider with a local presence and a global reach. We bring generations of experience to the development of closures that protect products and enhance usability.

Product Integrity

Innovative Solutions that Protect Products from Tampering or Misuse

For generations, we have designed closures that balance security, safety, and usability. Our experienced team has developed a broad range of off-the-shelf, market-leading closure solutions that protect both products and consumers.

Sustainability

A Crucial Element of Modern Packaging Design

Sustainable packaging design is growing in importance as consumers, regulators, and stakeholders increasingly hold companies accountable for their waste and greenhouse gas emissions. BERICAP can help you develop solutions that maximize the product experience while minimizing waste.

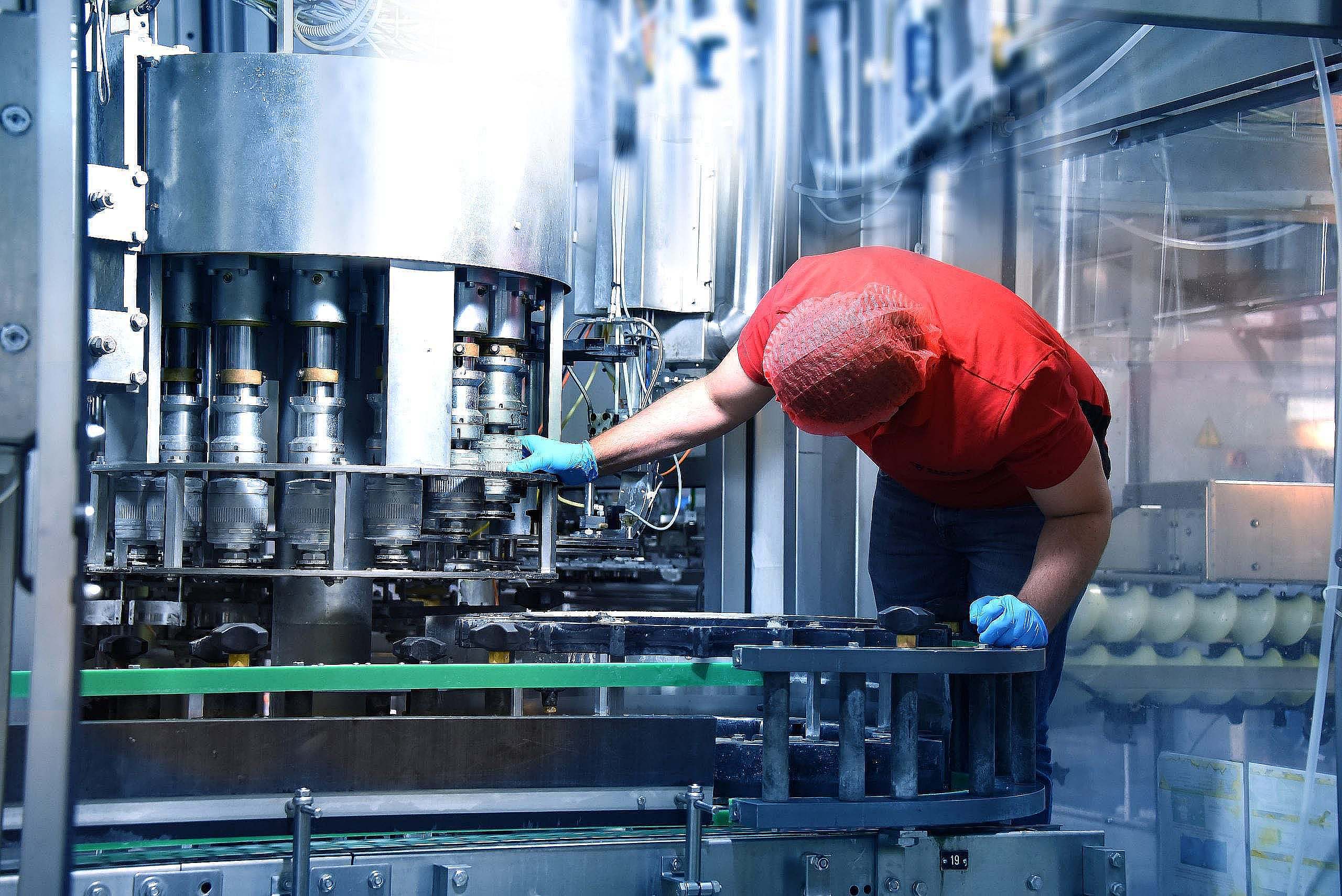

Operational Excellence

Streamlining Processes to Optimize Closure Development

Recent years have shown the importance of a robust and flexible supply chain. At BERICAP, our local production facilities are supported by a global network that can quickly pivot and respond to market conditions to maximize the return on your investment.

Questions?

How can we help you? Select the option that best meets your needs.